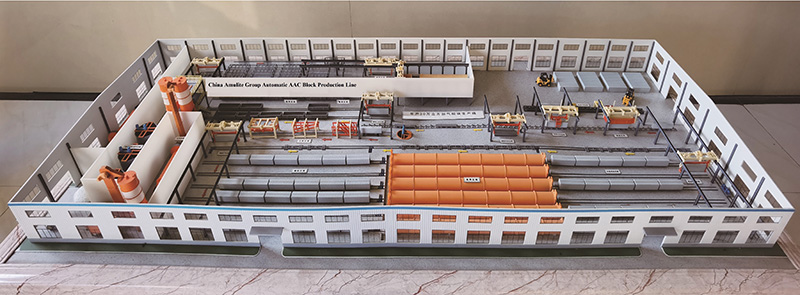

Amulite Tsis Siv Neeg AAC Thaiv Kab Ntau Lawm

Lus piav qhia luv luv:

Product Detail

Khoom cim npe

AAC Block yog dab tsi?

Lub tswv yim ntawm AAC Block: AAC Block yog raws li cov ntaub ntawv Siliceous (Xuab zeb, ya tshauv, Silica-muaj cov ntaub ntawv thiab lwm yam), thiab calcareous cov ntaub ntawv (txiv qaub, cement) raws li cov ntaub ntawv tseem ceeb, sib xyaw nrog Air-Entraining Agents (Aluminium Powder) Tom qab cov txheej txheem Raw Materials Batching, Slurry Mixing, Pouring, Pre-Curing, Cutting, Autoclave, Curing Process and Package to Produce Out AAC Blocks Finished Products; Nws yog hu ua Aerated Concrete vim nws muaj ntau tus qauv thiab me pores tom qab. Nws yog Aerated.

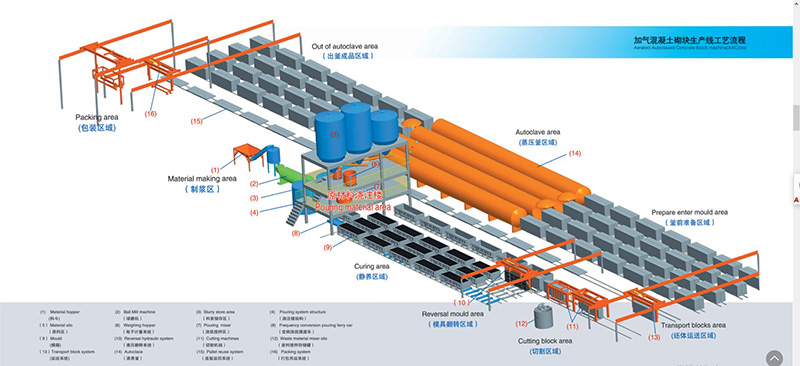

Dab tsi yog Tus Txheej Txheem Los Tsim AAC Thaiv Cov Khoom?

Dab tsi yog Tus Txheej Txheem Los Tsim AAC Thaiv Cov Khoom?

1) : Txhua Raw Materials Metering Thiab Mixed Slurry;

2) : Slurry nkag mus rau hauv Pouring System, Tom qab sib tov ces ncuav rau hauv lub thawv pwm;

3) : Sab hauv Pwm Box (Vaj Huam Sib Luag Reinforcement), Tom Qab Qee Qhov Kub Thiab Lub Sij Hawm Ua Ntej;

4) : Tom qab lub vaj huam sib luag ntub dej ncav cuag ib qho nyuaj, lub thawv pwm thiab cov vaj huam sib luag yuav raug nqa mus rau lub tshuab txiav los ntawm kev hloov pauv Crane, thiab cov Crane Turnover ua tiav cov haujlwm hauv qab no:

5) : A: Yog Yuav Tig Lub Thawv Pwm 90 Degree Hauv Huab Cua, (Ib Sab Ntawm Lub Thawv Pwm Ua Tus Txhawb Nqa Trolley Phaj Rau Lub Vaj Huam Sib Luag ntub dej kom txog thaum Autoclave txheej txheem tiav),

6) : B : Yog To Hoist Rau Lub Trolley lossis Cov Txheej Txheem Txiav Txim kom qhib lub pwm kom tiav; C: Tshem tawm Pwm Ncej Thiab Rov Qab Autoclave Sab Phaj Rov Qab Los Ua Ib Lub Thawv Pwm Tom Qab Ntxuav, Txau Roj Thiab Rov Qab. Ncuav;

7) : Thiab Cov Vaj Huam Sib Luag ntub dej yog txiav rau 6 kauj ruam ntawm lub tshuab txiav: 1: Ua ntej txiav ob sab ntawm lub vaj huam sib luag ntsug; 2: Tom qab txiav ntev thiab kab rov tav;

8) : Thaum kawg txiav kab rov tav kab rov tav lossis riam txiav;

9) : Lub Cev Vaj Huam Sib Luag Lub Cev Hoisted Los ntawm Semi-Tiav Khoom Crane Ua Ke Nrog Cov Phaj Hauv Qab Rau Autoclave Trolley;

10) : Tom qab ntawd muab tso rau hauv Autoclave rau kub kub thiab kub siab kho;

11) : Tom qab Zoo Autoclave Curing, Lub Trolley yuav raug tshem tawm thiab tawm hauv Autoclave;

12) : Cov khoom tiav yog stacked lossis Loaded ntawm lub tsheb thauj khoom los ntawm cov khoom tiav Hosting Crane, Ntim Zoo;

13): Lub Autoclave Curing Sab Phaj Rov Qab;

Hais txog Main Raw Materials Taw qhia

Kev Tsim Khoom Ntawm AAC Block yog nplua nuj nyob rau hauv cov khoom siv raw, tshwj xeeb tshaj yog siv cov tshauv ya raws li cov khoom siv raw uas tsis tuaj yeem siv tsuas yog siv cov khib nyiab pov tseg, kho ib puag ncig muaj kuab paug, thiab tsis ua rau thaj av puas tsuaj, tab sis kuj tsim txiaj ntsig zoo rau kev noj qab haus huv thiab nyiaj txiag, nws Yog Ib qho zoo hloov pauv rau cov khoom siv av nplaum zoo ib txwm muaj.Zoo cog lus cov khoom siv phab ntsa tau zoo siab txais tos los ntawm tsoomfwv, tuam txhab vaj tse, pab pawg tsim kho, thiab tsoomfwv tau tsim txoj cai se, kev tiv thaiv ib puag ncig, peb tuaj yeem pom kev lag luam dav dav;

1. ya tshauv/quartz xuab zeb

Fly tshauv / Quartz xuab zeb yog lub ntsiab tseem ceeb ntawm cov khoom siv raw ntawm AAC thaiv cov khoom, thiab yog lub hauv paus tseem ceeb ntawm Silicon thiab Aluminium Cheebtsam ntawm Aerated Concrete;

2. Cement

Cement yog qhov tseem ceeb ntawm lub zog ntawm AAC Block, Nws muab cov ntaub ntawv tseem ceeb Calcareous rau AAC Block, cement haum rau kev tsim cov AAC Block yuav tsum tau xaiv feem ntau ntawm hom thiab qib ntawm cement; Hauv ntau lawm, 52.5 Qib Ordinary Portland Cement yuav tsum tau xaiv ua ntej .Nyob rau hauv dav dav, Yuav kom txo tau cov nqi ntau lawm, 42.5 Qib Ordinary Portland Cement yuav siv tau thiab;

3. Txiv qaub

Txiv qaub kuj yog ib qho ntawm cov khoom siv tseem ceeb rau kev tsim cov AAC Blocks.Nws lub luag haujlwm tseem ceeb yog kev koom tes nrog cov cement kom muaj txiaj ntsig zoo Calcium Oxide, yog li nws tuaj yeem cuam tshuam nrog SIO2 thiab Al203 hauv Siliceous Cov ntaub ntawv raws li Hydrothermal Conditions los tsim Silicon Hydrate Calcium Acid.Yog li ntawd, txiv qaub yog ib qho ntawm lub zog tseem ceeb ntawm AAC Block.Cov txiaj ntsig Calcium Oxide Cov ntsiab lus ntawm txiv qaub siv los tsim AAC Block yuav tsum siab dua 65%, nyiam dua siab dua 80%.

4. Gypsum

Gypsum yog ib tug Regulator ntawm cov huab cua evolution txheej txheem nyob rau hauv AAC thaiv ntau lawm.The Regulating Effect Of Gypsum is Mainly Reflected In The Delay of Quicklime digestion and Slurry Thickening Speed.The Main Chemical Chemical Chemical Chemical Chemical Chemical Chemical Cheebtsam Ntawm Gypsum yog CASO4; Muaj peb hom Gypsum ntawm Cov. Kev ua lag luam; Raw Gypsum, Anhydrite thiab Plaster ntawm Paris.Ntxiv, pov tseg gypsum tseem tsim nyob rau hauv cov txheej txheem tsim tshuaj.Xws li Phosphogypsum Los Ntawm Kev Tsim Cov Phosphate Fertilizers, Fluorogypsum Los Ntawm Kev Tsim Cov Tshuaj Fluorine, Thiab Gypsum Los Ntawm Kev Tsim Khoom Ntawm Titanium Dioxide.Cov Gypsum no yog tus nqi qis thiab tuaj yeem hloov cov gypsum ntuj thiab txo cov nqi tsim khoom;

5. Huab cua tsim tus neeg sawv cev

AAC Block yuav tsum muaj ib tus neeg sawv cev tsim hluav taws xob los tsim cov pores hauv qhov thaiv kom tsim tau lub teeb porous;

6. Ua npuas ncauj Stabilizer

Tom qab Cov Cuab Yeej Siv Hluav Taws Xob Gasses, Vim yog Phab ntsa nyias nyias, nws yooj yim rau tawg thiab rhuav tshem cov npuas dej raws li kev cuam tshuam ntawm ntau yam xwm txheej, uas cuam tshuam rau qhov zoo ntawm cov pob zeb. Yog li ntawd, nws yog ib qho tsim nyog yuav tsum tau ntxiv Foam Stabilizer rau Cov. Slurry.

Txheej txheem ntau lawm

1) : Cia thiab Muab Cov Khoom Raw Rau AAC Block

Raw Materials raug thauj mus rau hauv lub Hoobkas los ntawm tsheb, thiab ya (xuab zeb, pob zeb hmoov) yog nyob rau hauv cov ntaub ntawv raw khoom, thiab thaum siv, nws yog thauj mus rau hauv lub Hopper.Bagged Cement los yog tej cement yog khaws cia rau hauv lub Cement Warehouse.Thaum twg Nyob rau hauv kev siv, Nws yog Loaded thiab thauj mus rau hauv lub Hopper.Chemicals, Aluminium Powder Etc yog muab tso rau hauv cov tshuaj cia thiab txhuas hmoov cia, raws li, thiab xa mus rau lub ntau lawm Rhiav thaum siv.

2) ![]() rocessing Ntawm Raw Khoom Rau AAC Blocks

rocessing Ntawm Raw Khoom Rau AAC Blocks

Fly tshauv (los yog xuab zeb, pob zeb hmoov) raug xa mus rau lub pob zeb los ntawm electromagnetic vibrating feeder thiab siv conveyor, Thiab cov av ya tshauv (los yog xuab zeb, pob zeb hmoov) raug xa mus rau lub Slurry Tank rau cia los ntawm Fly tshauv twj tso kua mis.

Cov txiv qaub raug xa mus rau lub puab tsaig crusher los ntawm Electromagnetic vibrating feeder thiab siv conveyor rau crushing.Lub txiv qaub crushed yog xa mus rau txiv qaub cia Tank los ntawm lub thoob of elevator, thiab ces xa mus rau lub pob zeb los ntawm cov ntsia hlau conveyor.Cov ntsia hlau conveyor thiab Lub thoob of elevator tau pub rau hauv cov hmoov batching Tank.Tom qab cov tshuaj raug ntsuas los ntawm ib qho kev faib ua feem, ib qho kev daws teeb meem ntawm qee qhov concentration yog tsim thiab xa mus rau lub tank cia rau cia.

Cov hmoov txhuas yog xa tawm los ntawm Aluminium hmoov warehouse mus rau qhov kev cob qhia ntau lawm, thiab tau nqa mus rau theem ob ntawm lub tsev batching nrog ib lub tshuab hluav taws xob.

3) Slurry Mixing, Thiab Pouring ntawm AAC Blocks;

Txiv qaub thiab Cement raug xa mus rau qhov Tsis Siv Neeg Weighing Scale Los Ntawm Cov Ntsia Hlau Conveyor Hauv Qab Cov Hmoov batching Tank Rau Kev Ntsuas Kev Ntsuas.Muaj Ib Lub Ntsia Hlau Conveyor Nyob rau hauv qhov ntsuas kom sib npaug ntxiv cov ntaub ntawv rau hauv cov khoom sib tov.

Fly tshauv (los yog xuab zeb, pob zeb hmoov) thiab cov khib nyiab slurry muab tso rau hauv lub tog raj kheej ntsuas rau kev ntsuas.Tom qab ntau yam khoom raug ntsuas, pwm nyob rau hauv qhov chaw, thiab cov slurry tuaj yeem stirred.Lub slurry yuav tsum tau raws li cov txheej txheem yuav tsum tau (kwv yees li 45). ℃) Ua ntej Pouring.Yog tias qhov kub tsis txaus, Autoclave cua sov tuaj yeem nqa tawm hauv Slurry Metering Tank, Thiab Cov Khoom Siv Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas Txhuas

4) : AAC Thaiv Ua Ntej Kho Thiab Txiav

Tom qab pouring, Lub thawv pwm raug thawb mus rau hauv qhov pib Curing chav los ntawm ib lub conveyor saw rau Gasification thiab pib qhov chaw.Theem kub yog 50 ~ 70 ℃, Thiab lub sij hawm pib kho yog 1.5-2Hours (Raws li qhov haum rau thaj chaw, qhov no Cov txheej txheem tuaj yeem raug tshem tawm).Siv lub siab tsis zoo hoist los nqa cov pwm ncej thiab lub cev ntub dej rau ntawm lub rooj txiav qhov chaw hauv qab phaj ntawm Autoclave trolley tau muab tso rau hauv ua ntej.Tawm lub pwm ncej.Lub tshuab txiav hla-txiav. , Longitudinally Cuts, Thiab Mills Qhov Ncauj Ntsig.Lub Pwm Ncej yog hoisted rov qab mus rau Pwm Truck kom huv si thiab degreasing, thiab ces nqa mus rau lub pwm tsheb rau lub tom ntej Casting.Lub txiav thaiv lub cev thiab lub qab phaj ntawm lub Autoclave yog hoisted rau ntawm lub Autoclave Trolley nrog ib tug Crane thiab muab tso rau. Ob Pem Teb.Nws muaj plaub qhov kev txhawb nqa nruab nrab ntawm Cov Pem Teb, Thiab Ob peb Autoclave Trolley tau muab tso ua ke.

Cov ntaub ntawv pov tseg ntawm ntug thiab kaum ntawm lub cev ntub dej uas tsim tawm thaum txiav raug xa mus rau cov khib nyiab slurry agitator tom ntej no mus rau lub tshuab txiav los ntawm cov ntsia hlau conveyor, thiab dej ntxiv los ua cov khib nyiab slurry siv hauv batching.

5) : Autoclaved AAC Thaiv Thiab Cov Khoom tiav.

Tom qab lub cev tau muab tso rau ntawm qhov chaw nres tsheb nyob rau hauv pem hauv ntej ntawm lub Autoclave, qhib lub qhov rooj Autoclave uas tawm ntawm lub autoclave, ua ntej rub tawm lub tiav Autoclave Trolley nyob rau hauv lub autoclave nrog ib tug hoist, thiab ces rub lub Autoclave Trolley mus rau Autoclaved. Nyob rau hauv Lub Autoclave Nrog Ib Tug Hoist Lub Autoclave tau tswj xyuas.Cov khoom tiav ntawm Autoclave Trolley yog Hoisted rau cov khoom tiav Warehouse los ntawm ib tug Choj Crane, thiab ces thauj mus rau cov khoom tiav lawm yard los ntawm ib tug Forklift Truck.The Empty Autoclave Trolley Thiab hauv qab Phaj ntawm Autoclave khiav yog hoisted rov qab mus rau lub carriage rov kab, thiab cov stacker yog rub rov qab los ntawm ib tug hoist tom qab ntxuav. Mus rau lub voj voog tom ntej.

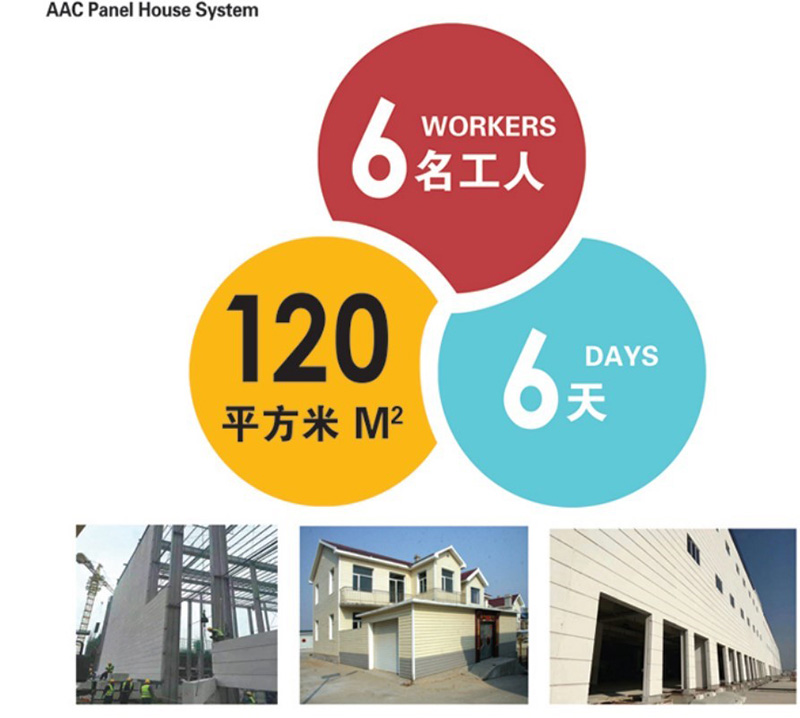

Cov cuab yeej siv ntau lawm Show

1): Cov khoom sib tsoo thiab ua Slurry Tshooj

| Cov txheej txheem ib txwm ua ntawm Slurry Density Control tsis nruj .Qhov ceev ntawm Protoplasm yog feem ntau dhau los ntawm Artificial Measurement .Qhov yuam kev loj dua .Qhov ceev ntawm Circulating Plasma Basic yog siv los tswj raws li kev paub .Yog li hauv kev tsim cov khoom lag luam qib siab qis. .Qualified Rate thiab cov khoom zoo tsis zoo tagnrho .Qhov ceev ntawm Amulite siv txoj kev ntsuas kav kav dej tshiab muaj qhov zoo hauv qab no1.Lub Slurry yog ncig ntawm lub tank thiab lub densimeter, cov ntaub ntawv Slurry ntom yog ntsuas los ntawm cov kav dej ntom ntom hauv cov txiv qaub tiag tiag thiab cov lus teb rau hauv Central Control Room .Txhim kho cov dej sib piv ntawm Pulping ntawm lub pob zeb thiab cov filling. Ntawm Lub Slurry Tank .Lub hom phiaj ntawm kev kho tsis tu ncua ntawm Real-time ceev yog ua tiav:2.Cov yeeb nkab ntom ntom yuav tsum ntsuas qhov siab ntawm tag nrho cov slurry . ntsuas qhov tseeb yam tsis muaj qhov yuam kev .Thiab tom qab ntawd yaug tag nrho cov yeeb nkab tom qab ua haujlwm kom paub tseeb qhov tseeb ntawm qhov ntsuas tom ntej. |  | |||

| ||||

| Fly tshauv Slurry Ua Tshuab | Slurry Storage Tov Khoom | Khoom ntsuas | Pouring System | |

| 2): Kev hloov pauv thiab ntu ntu | ||||

Lub ntsiab nta ntawm Amulite txiav tshuab1): Yooj yim-Structured, yooj yim rau nruab thiab tswj;2) : Tsau rau hauv av, tsav los ntawm Ntiaj Teb-Gear Reducer, thaum ua ntsug txiav, lub tshuab txiav ua eccentric thiab viav vias txiav uas ua rau kev txiav txiav ua kom yooj yim dua los hloov txiav loj. Lub ntsiab nta ntawm Amulite txiav tshuab1): Yooj yim-Structured, yooj yim rau nruab thiab tswj;2) : Tsau rau hauv av, tsav los ntawm Ntiaj Teb-Gear Reducer, thaum ua ntsug txiav, lub tshuab txiav ua eccentric thiab viav vias txiav uas ua rau kev txiav txiav ua kom yooj yim dua los hloov txiav loj. 3) : Absorbing German Technology, Ntxiv Nqus Aspirator, Lub Tshuab Txiav no tuaj yeem tshem tawm cov ntaub ntawv pov tseg saum toj no yooj yim yam tsis muaj kev puas tsuaj ib feem ntawm cov blocks tiav thiab paub tseeb tias cov khoom dhau tus nqi; 4) : Nrog 6-sab txiav ntawm tag nrho cov thaiv, cov khoom Pass tus nqi nce ntxiv vim tias cov khoom tiav tiav yuav tsis cuam tshuam los ntawm kev hloov pauv pwm ntxiv. 5) : Siab Roughness Ntawm Qhov Nto Ntawm Cov Blocks tiav yog qhov zoo rau kev tsim kho thiab kev tsim kho. 6) : Txais Txoj Haujlwm Kev Tswj Xyuas Kev Siv Tshuab, Lub Tshuab no txo qis kev co hauv cov txheej txheem ntawm kev tig, txav, txiav thiab thauj. Tsis tas li ntawd, nws tuaj yeem hloov kho rau PLC tswj qhov system ntawm qhov kev thov ntawm cov neeg siv khoom kom nce cov khoom xa tuaj. | ||||

| ||||

| Hydraulic zaus Hloov Turnover Crane | Kab rov tav txiav tshuab | |||

| 1) : Hydraulic zaus Hloov Turnover Crane Hloov Pwm Lub Thawv Nrog Thaiv Hauv 90 Degree Turnover, Muab Nws Rau Ntawm Cov Zaus Hloov Block Dragging Trolley Thiab Txheej Txheem Ua Haujlwm;2) : Ntau zaus Hloov Block Dragging Trolley Drags Lub Thaiv rau Txiav Tshuab Txiav.Turnover Crane Reorganizes, Cleans Thiab Polishes Pwm Lub Thawv Thiab Pallets los npaj lawv rov qab siv dua. | Turnover Crane Tig Lub Pwm 90 Degree, Demould Thiab Muab Tag Nrho Cov Thaiv Thiab Cov Phaj Hauv Qab Rau Block Dragging Trolley.Lub Block Dragging Trolley yuav muab tag nrho cov thaiv rau hauv lub tshuab txiav, thiab ua tiav kab rov tav txiav, Tev tag nrho cov thaiv los ntawm ob sab, thiab sib cais. Cov ntaub ntawv pov tseg. | |||

| ||||

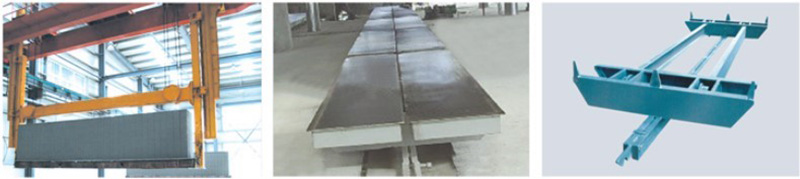

| 3): Turnover Crane Tshem Tawm Cov Khoom Siv Hauv Qab | ||||||||||

| Cov cuab yeej no yog tsim los ntawm pab pawg Amulite los pab peb cov neeg siv khoom daws teeb meem hauv qab cov khoom pov tseg.Cov cuab yeej no suav nrog Turnover Platform thiab Crane, Nws tuaj yeem tshem tawm cov khoom siv khib nyiab sab saum toj thiab hauv qab.No Crane kuj tuaj yeem ua tau raws li cov khoom thauj khoom ib nrab. | |||||||||

| Thauj Crane Ua Ntej Autoclave | Base Phaj | Autoclave Trolley | ||||||||

| ||||||||||

| Tom qab txiav, Tsheb thauj mus los Crane Nqa Thaiv Rau Autoclave Trolley Rau Nkag Autoclave.Cov cuab yeej no muaj cov qauv yooj yim, ruaj khov ua haujlwm, zoo zoo thiab yooj yim los tswj. | Lub hauv paus phaj tsim los ntawm pawg Amulite tuaj yeem ua rau sab phaj, tsis tas yuav hloov mus txog thaum tawm ntawm Autoclave.Nws yog tsim los ntawm Manganese hlau thiab tsis txhob deformation nyob rau hauv qhov kub thiab txias. | Nws yog tsim los ntawm cov khoom zoo Profile hlau thiab muaj cov qauv yooj yim .Stuck Thiab Distortion yuav tsis tshwm sim hauv qhov kub thiab txias Autocalve Curing ib puag ncig hauv Autocalve.The Crane muab cov ntub thaiv rau ntawm Autocalve Curing Trolley Thiab mus rau hauv Autoclave Yuav Autoclave Txuag Kom txog rau thaum tshem cov Blocks tiav; | ||||||||

| 4): Cov khoom siv ua tiav tiav | ||||||||||

| Feem ntau Cov Autoclaved Blocks Thiab Phaj yuav muaj Adhesions Qee zaum.Lub tshuab Seperating yog ua kom tiav cais cov Adhesion Blocks yam tsis muaj kev puas tsuaj rau cov blocks, uas sib xyaw ua haujlwm ntawm cov tsoos sib cais tshuab thiab cov khoom tiav tiav.Txhua tes sib cais yog tswj tau ywj siab, Kev daws qhov teeb meem ntawm kev sib cais cov blocks thiab panels ntawm tib lub pwm; Cov cuab yeej ua tiav kev ua haujlwm zoo thiab maj mam, txo tus nqi tag nrho thiab ua kom tus nqi zoo tib lub sijhawm. | |||||||||

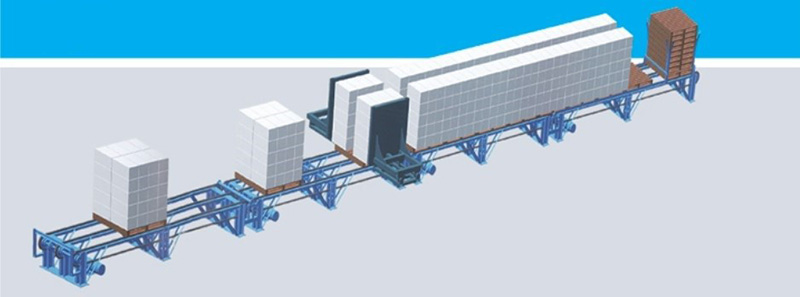

| Convey And Package Line | ||||||||||

| ||||||||||

| Cov kab ke no suav nrog kev xa tawm thiab ntim kab rau cov ntoo pallets uas yog tsim los rau cov tiav AAC Blocks.Cov khoom pwm tag nrho yuav raug txav mus rau cov ntoo pallet ib zaug los ntawm txhais tau tias Clamping ntaus ntawv rau cov khoom tiav rau kev xa khoom ntxiv thiab ntim rau. Cov Kab no.Lub tshuab no muaj cov yam ntxwv zoo li tsis siv neeg faib los ntawm kev tswj hwm lub khoos phis tawj, qhov chaw ruaj khov thaum lub sij hawm thauj khoom thiab tsis siv neeg sib cais ntawm Loaded Ntoo Pallet Nyob rau hauv rooj plaub twg nws yog qhov yooj yim rau ntim thiab xa khoom. | ||||||||||

| 5): Ntau Tshuab Qhia | ||||||||||

Cov khoom tiav Clamp Cov khoom tiav Clamp |  Rotary Clamp Rotary Clamp | |||||||||

| ||||||||||

| Tshwj xeeb Crane Rau Panels | Plug Tshuab | Qhib Slot Machine | ||||||||

| ||||||||||

| Pob Zeb | Lub puab tsaig Crusher | Autoclave | Boiler | |||||||

| ||||||||||