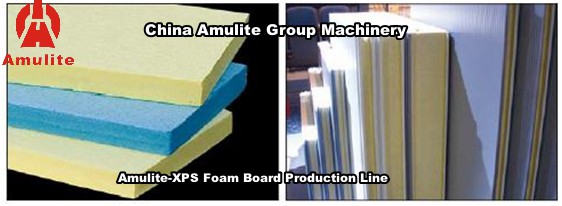

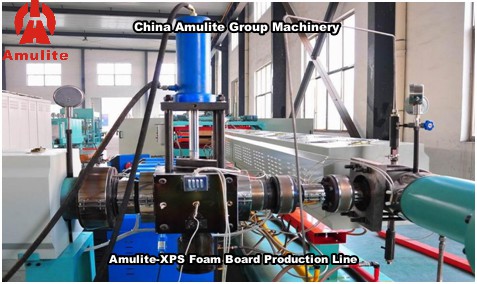

Amulite CO2 XPS Ua Npuas Ncauj Board Ntau Lawm Kab

Lus piav qhia luv luv:

I.Technical Introduction

Ua ntej, compounding symmetrical1y XPS cov ntaub ntawv nrog rau lwm cov ntaub ntawv pab xws li nucleant tus neeg saib xyuas thiab xim batch; Secondly muab lawv mus rau hauv hopper ntawm Qib Iextruder los ntawm lub tshuab nqus tsev feeder automatical1y; Thib peb melting thiab plasticizing resin byspecial1y tsim ntsia hlau symmetrically, tib lub sij hawm txhaj tshuaj ua npuas ncauj los ntawm siab. nws nrog melted resin; Plaub, muab tso rau hauv Qib IIextrusion system rau meit, sib tov, ntxiv siab thiab txias dua thiab extruding ua npuas ncauj boardby tshwj xeeb pwm rau board, ces txias thiab tsim board los ntawm txias thiab formingdexiss..kifthly.muab lub rooj tsavxwm rau hauv Qib I kos-tawm qhov system thiab thauj mus rau Qib Il kos-tawm system los ntawm kev thauj mus los rol1s;Sixthly, txiav pov tseg ntug bysaw ntawm ob sab thiab ua tiav transverse txiav raws li teeb 1ength;qhov 1st kauj ruam, stacking thiab cia.

Product Detail

Khoom cim npe

Chav tsev hluav taws xob:

Main lub cev muaj zog Beide Hom (Siemens Standard Motors Ltd.)

Transducer Danfoss lossis Siemens Brand

AC Contactor Siemens los yog Schneider Hom Kub Controller Meter Omron Hom lossis Fuji Hom Voltage 380V, 50HZ

AM-XPS75P/200 CO2XPS Ua Npuas Ncauj Board Ntau Lawm Kab

Kuv.Tshuabal Taw qhia

Ua ntej, compounding symmetrically XPS cov ntaub ntawv nrog rau lwm cov ntaub ntawv pab xws li nucleant tus neeg saib xyuas thiab xim batch;Secondly muab tso rau hauv hopper ntawm Qib I extruder los ntawm lub tshuab nqus tsev feeder txiav;Thirdly melting thiab plasticizing resin los ntawm tshwj xeeb tsim ntsia hlau symmetrically, nyob rau tib lub sij hawm txhaj ua npuas ncauj tus neeg saib xyuas los ntawm kev kub siab thiab sib tov nrog melted resin;Plaub, muab lawv tso rau hauv Qib II extrusion system kom yaj, sib tov, ntxiv siab thiab txias dua thiab extruding ua npuas ncauj board los ntawm tshwj xeeb pwm rau lub rooj tsavxwm, ces txias thiab tsim board los ntawm txias thiab tsim ntaus ntawv; Fifthly, muab lub rooj tsavxwm rau qib kuv kos- tawm ntawm qhov system thiab thauj lawv

mus rau Qib II kos-tawm system los ntawm kev thauj mus los yob;Sixthly, txiav pov tseg ntug los ntawm

pom ntawm ob sab thiab ua tiav transverse txiav raws li qhov ntev;cov kauj ruam kawg, stacking thiab cia.

II.Lub Main Khoom siv

1> XPS resin

2> Tus neeg ua npuas ncauj & pab ua npuas ncauj 3> Tus neeg sawv cev Nucleant

4> Xim batch

5> Lwm cov ntaub ntawv pab

Nco tseg: Peb yuav muab peb cov neeg siv khoom nrog cov ntawv sau, hom khoom thiab cov ntaub ntawv txheeb ze tom qab kos npe rau daim ntawv cog lus.

Tshuab Component

1> Yas tov khoom 1 teeb

2> Qib I extrusion system 1 teeb

3> CO2ua npuas ncauj tshuaj txhaj tshuaj system 1 teeb 4> Pab neeg ua npuas ncauj tshuaj txhaj tshuaj system 1 teeb 5> CO2flow show system 1 teeb 6> HCFC Ua Npuas Ncauj Tus neeg saib xyuas qhov system 1 teeb 7> Tsis siv neeg net-exchange system 1 teeb

8> Qib II extrusion system 1 teeb

9> Extrusion tuag taub hau 1 teeb

10> Calibrating thiab kos-tawm system 1 teeb

11> Kev xa tawm thiab cua txias 1 teeb

12> Qib II kos-tawm system 1 teeb

13> Lengthways txiav system 1 teeb

14> Kab rov tav txiav system 1 teeb

AM-75 P/200 CO2XPS Foamed Board Ntau Lawm Kab

1.Pub qhov system

2.AM75/44 ibTwin-ntsia hlau extruder 1 teeb

3.CO2ua npuas ncauj tshuaj txhaj system 1 teeb

4.Pab neeg ua npuas ncauj txhaj tshuaj qhov system 1set ib

5.Freon Foam tus neeg saib xyuas kev txhaj tshuaj 1 teeb

6.CO2ntws ua yeeb yam qhov system 1set ib

7.Tsis siv neeg net- pauv qhov system 1set ib

8.Qib II extrusion qhov system 1 teeb

9.Extrusion tuag taub hau 1set ib

10.Calibrating thiab kos-off system 1 teeb

11.Transmission thiab cua txias system 1 teeb

12.Qib II rub tawm qhov system 1set ib

13.Ntev ntev txiav qhov system 1set ib

14.Kab rov tav txiav qhov system 1set ib

15> Transverse txiav qhov system 1set ib

15.Chav tsev hluav taws xob

XPS Foamed Board Recycling thiab Pelletizer Tshuab

Qauv AM-XPS-JR100B

1> XPS ua npuas ncauj board crusher ntaus ntawv 1set ib

2> Ib leeg ntsia hlau plasticizing thiab extrusion ntaus ntawv 1set ib

3> Lim net-hloov ntaus ntawv 1 teeb

4 > Txias tank 1set ib

5> Txiav pellet tshuab 1set ib

Nco tseg: Cov kev faib ua feem saum toj no ntawm tus neeg sawv cev ua npuas ncauj tsuas yog rau koj siv, cov ntaub ntawv tiag tiag raug kho raws li qhov xav tau ntawm cov khoom siv raw thiab kev ua lag luam.