Cov txheej txheem tsim khoom pib

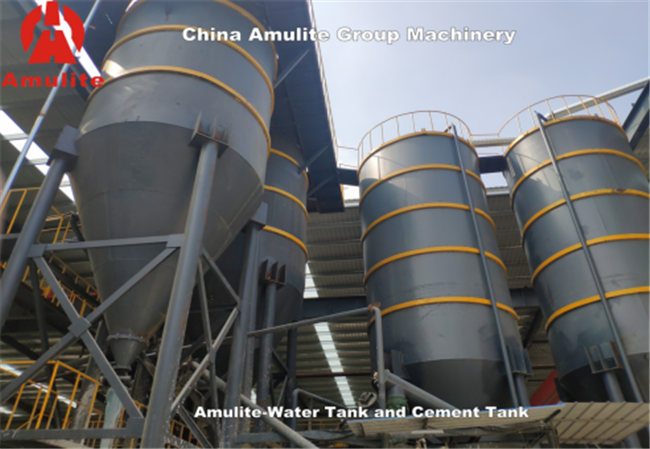

1. Dej Tank Thiab Cement Tank Txheej Txheem

Muaj ib lub tank dej huv thiab ib lub tank dej nkos; Ob lub tank lub cev yog welded los ntawm carbon hlau, Lub tank dej nkos yog siv los sau rov qab cov dej rov qab los ntawm cov txheej txheem ntau lawm, dej nkos coj mus sib tov rau hauv slurry txheej txheem, kom huv si Lub tank dej yog siv los nqa dej huv los ntxuav Felt thiab Net tawb Nquag.

2.Paper Pulp txheej txheem

Daim Ntawv Pulp Txheej Txheem suav nrog Daim Ntawv Shredder Tshuab, Refiner, Thiab Ntawv Pulp Cia Tank

Daim ntawv Shredder yog siv los txiav cov ntawv Kraft

Refiner Siv Los Sib Tsoo Cov Ntawv Pulp Ua Slurry Thiab Pumping Lawv mus rau Daim Ntawv Pulp Cia Tank.

Paper Pulp Storage Tank yog siv los khaws cov ntawv Pulp.

3. Flow-On Slurry Vacuum Water Dehydration Process

Muaj peev xwm xaiv Flow-On Slurry Forming Sheets System lossis Hatschek Hom Kev Sau Cov Ntawv Txheej Txheem Rau Daim Ntawv, Peb tuaj yeem kho raws li cov neeg siv khoom xav tau.

Zoo sib xyaw Slurry Flow mus rau hauv Flow-On Slurry Box, Tom qab ntawd los ntawm Slurry Box Convey mus rau khiav Felt rau daim ntawv Slurry txheej, nrog lub tshuab nqus tsev nqus dej thiab lub hauv siab cov menyuam nias rau daim ntawv txheej, Tom qab txheej dov Round sib sau cov ntawv nruas cov menyuam, ces txiav mus rau hauv daim ntawv. Form Flat Wet Sheets.

Cua-Dej Separator: Nws yog siv los cais cov chav dej sib tov tawm los ntawm lub tshuab nqus tsev, ntws mus rau hauv qhov chaw khaws cia, thiab huab cua tau xa rov qab mus rau lub tshuab nqus tsev twj.

4.Flow-On Slurry Sheet txheej txheem

Tom qab sib sau cov menyuam ua cov ntawv, tom qab ntawd nrog tsis siv neeg Laser Positioning thiab txiav, tag nrho PC ntawm cov ntawv ntub dej nkag mus rau hauv cov txheej txheem.

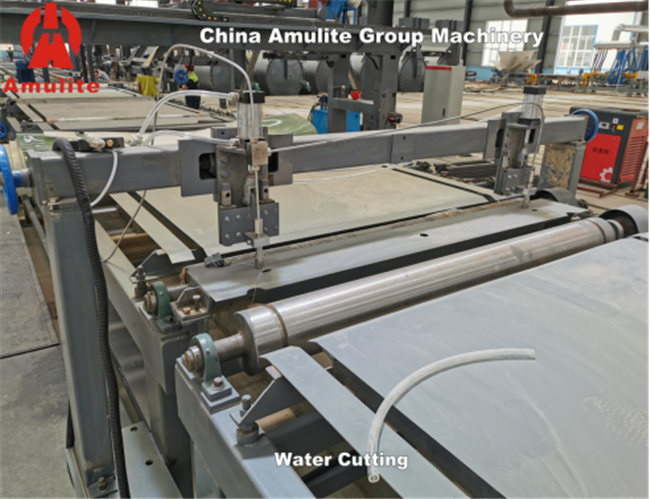

5.High Pressure Water Cutting System

Qhov no High Pressure Water Cutting System yog peb tus kheej cov cuab yeej patent, nrog cov twj tso kua dej siab tuaj yeem ua kom cov dej siab siab kom huv si txiav cov ntawv ntub dej ntawm cov khoom siv.

6.Kev tsim cov ntawv ntub dej thiab cov ntawv ntub cov txheej txheem

Cov txheej txheem no yog siv los xa cov ntawv hlais zoo ntub los ntawm kev tsim cov menyuam yaus xa cov ntawv ntub dej mus rau qhov chaw thiab ua kom tsis siv neeg ntug txiav.

7. Tsis siv neeg Stacker

Ob daim ntawv tuaj yeem muab tso rau hauv ib lub sijhawm.Lub Suction khob nqus cov ntawv ntub dej los ntawm kev txais lub tshuab nqus tsev thiab cov qauv ntawm lub trolley ntawm lwm txoj haujlwm ua haujlwm, thiab tom qab ntawd muab lawv tso rau ntawm lub trolley ntawm qhov chaw nruab nrab (nrog Lub Nqus Suction ntawm High-Pressure Ntxuam).Qhov tseeb txav ntawm Suction khob yog pom tau los ntawm lub iav ntawm lub viav caj npab thawb los ntawm Hydraulic Push Rod.

PLC tswj, tsis siv neeg ua haujlwm.

Muaj nuj nqi: Tsis Siv Neeg Stacker yog siv los txheeb thiab stack qhov zoo thiab cov khoom tsis zoo ntawm Fiber Cement Board / Calcium Silicate Board.

Cov khoom yog Stacked Orderly thiab siab automated, uas yuav zoo txhim kho cov efficiency ntau lawm.

8 .Nias tshuab

Yog siv los ua kom qhov ntom ntom thiab muaj zog ntawm cov khoom,

Txheem Siab: 7000ton, Xovxwm Table Loj: 1350 * 2700 / 3200mm, Qhov nrug: 1200mm, Ua haujlwm stroke: 400mm, Siab ceev: 0.05 ~ 0.25mm / s;

Rov qab ceev: 15 mm / S

Hauv Thiab Tawm Ntawm Xov Xwm Tsheb Thauj Khoom: Ib Chav.

Lub Zog: 27.5kw

9.Trolley Traction System

Tso cai Load: 20T

Table Rail Inner Distance: 750mm

Taug kev Mechanism:

Tus Qauv Zauv: fa67-60-y-1.5, I = 50

Kev sib tw lub cev muaj zog: 1380r / min, Lub zog: 1.5kw

Taug kev ceev ntawm Trolley: 9m / min

10. Nqus Demoulding Template Tshuab

Kev txav ntawm lub tsheb thiab qhov nce thiab poob ntawm Suction khob yog tswj los ntawm Servo Tsav.

Lub Demoulding Template tshuab cais cov qauv thiab cov ntawv rau ntawm lub trolley, Cov Template muab tso rau ntawm cov roj txhuam tshuab kom txhuam cov roj, thiab cov ntawv yog muab tso rau ntawm lwm sab trolley.Ntxiv ib qho Autoclave Interleave Spacer Rau Txhua Daim Ntawv 150 hli.

Qhov tseeb txav ntawm Suction khob yog paub los ntawm lub iav ntawm lub viav caj npab thawb los ntawm Pneumatic Push Rod.

PLC tswj, tsis siv neeg ua haujlwm.

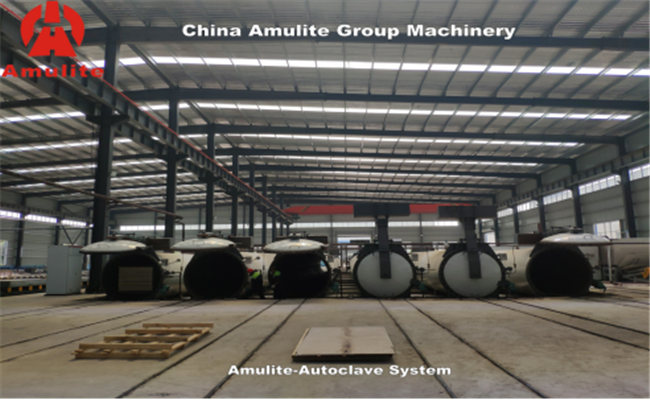

11.Autoclave txheej txheem

Vim yog cov yam ntxwv ntawm Fiber Cement Board / Calcium Silicate Board, txiv qaub thiab Quartz Sand Powder yog siv los ua cov khoom siv tseem ceeb hauv cov txheej txheem ntau lawm, uas yuav tsum tau txais cov tshuaj tiv thaiv nyob rau hauv qhov kub thiab txias ib puag ncig, muaj peev xwm cia tag nrho cov raw khoom sib tov. Zoo txaus, Thiab ua kom cov ntawv zoo dua hardness thiab muaj zog.

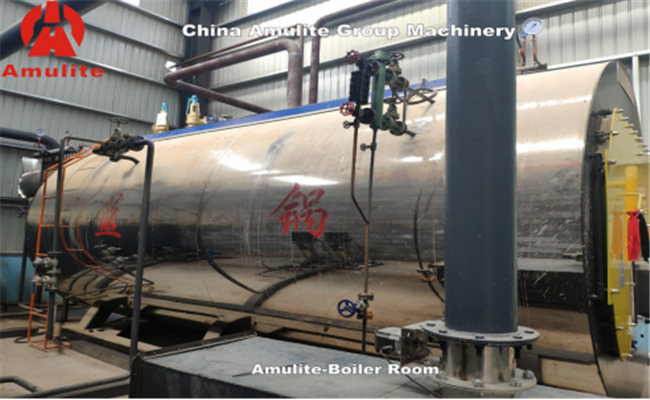

12. Boiler

Hauv Cov Txheej Txheem Ntau Lawm Ntawm Fiber Cement Board / Calcium Silicate Board, Autoclave thiab Tshuab ziab yog siv rau kev ua, thiab

Thaum tshav kub kub zog ntawm Autoclave thiab tshuab ziab khaub ncaws yog muab los ntawm boiler!

13. Lub tshuab ziab khaub ncaws

Nws yog siv rau ziab Fiber Cement Board / Calcium Silicate Board, Tom qab Autoclave Curing, Cov Khoom Moisture Ntawm Fiber Cement Board yog li 25%.Ua ntej Sanding, Edging Thiab Chamfering, Cov Moisture

Cov ntsiab lus yuav tsum tau txo qis dua 15% los ntawm lub tshuab ziab khaub ncaws.Lub tshuab ziab khaub ncaws muaj qhov zoo ntawm kev ua haujlwm siab, zoo nkauj tsos, kho yooj yim thiab ua haujlwm yooj yim.

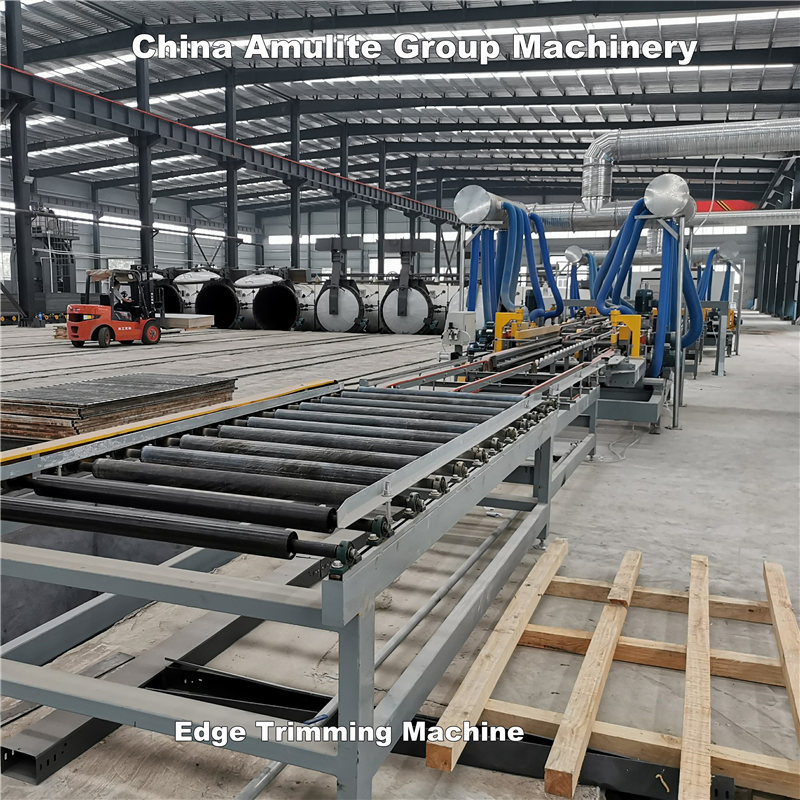

14. Edging Trimming System

Post lub sij hawm: Nov-02-2021